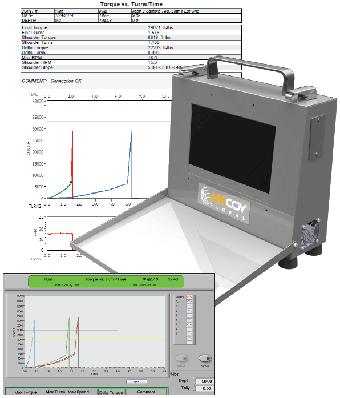

Pathmaker uses WinCatt software for our Computer Torque Monitoring services. WinCatt interacts with Pathmaker's control hardware providing real-time monitoring and control of tubular connection power tong make-up to ensure your connections are completed to the exact manufacturer's specification for premium connections shouldering time, delta torque, delta slope and delta turns. Pathmaker also uses WinCatt to provide a summary report of your make up results and to prepare torque graphs for each joint.

4 - WinnCATT Torque Monitoring systems with Back up systems

-certified every 6 months above Canadian Standard of 1 year-

Advantages:

Computer Torque Monitoring specifications

4 - WinnCATT Torque Monitoring systems with Back up systems

-certified every 6 months above Canadian Standard of 1 year-

Advantages:

- Record and report: Torque, turns, RPM, and where applicable, shoulder slope points for premium connections

- Technician runs the computer system - so that each graft can be analyzed before getting run in the hole

- Request correct alignment during make-up to prevent galling of threads

- Provide the customer with a detailed report of the make-up of each tubular connection, including rejected connections, this is produced by the computer software in the form of graphical joint reports, statistical reports, scattered charts, histograms, and pie charts.

- Intercede when necessary to help save connections from damage due to high RPM, over torque, over rotation, and alignment issues.

- When issues arise relating to connection make up, we ensure that hydraulic power to mitigate damages immediately.

Computer Torque Monitoring specifications